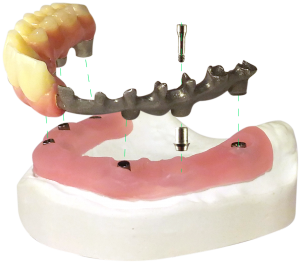

In collaboration with leading odontology laboratories and dental technicians, Ortho Baltic created patient – specific dental bar production technology, using medical titan alloy, based on 3D metal printing.

We use 3D data of patient to launch the process:

- Full virtual 3D pre surgical planning.

- Presuming optimal positions of standard implants, regarding the patient‘s bone and nerve condition, and projecting the solution of bar fixation.

- Creating dental bar, which is compatible with individual patient‘s parameters (implant type, position and fixation type).

- Correct occlusion is reconstructed, creating prosthesis of optimal geometry, which is fixed on the bar.

- Creating optimal mechanics of implant bar fixation.

- Creating surgical guide.

Applying planning and creating technologies by Ortho Baltic, the complex treatment solution is achieved virtually. In result any technical issues are avoided (such as changing the implant positions, adaptation of bars, fixing using cement, etc.). Our technology allows to freely chose the axes, elements of fixation, the number and type of implants used. All the parameters are changed without any damage or discomfort for the patient and are combined until the optimal surgical plan is achieved. The process then launches to production using 3D technology.

As the result of proper planning and manufacturing we receive the dental solutions of the new generation with the bars which can be repeatedly taken of and cleaned. Ortho Baltic technology of mechanical fixation allows to remove the bar multiple times and receive a professional hygiene procedure as usual. After this the construction is fixed back to it‘s exact position.

The solution offered by Ortho Baltic ensures minimal surgical invasiveness. This is the way how the implants can be fixed precisely, keep the nerve save from injury, allow the sufficient bone tissue.

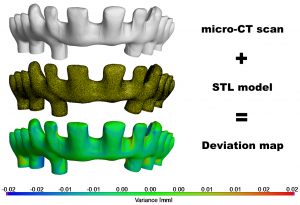

Special Attention to Quality Control

Dental bars altogether with the prosthetic solution All – on – (4 – 8) is especially complex medical device covering several stages of designing and manufacturing, and therefore requiring different expertise. That is why Ortho Baltic is carefully testing every single individually made bar in the laboratory of quality control. Controllers check the geometric measurements, seeking the compatibility with other elements as the implants, fixation abutment, fixation screws, crowns, esthetic part of the prosthesis and individual patient‘s anatomy.

Geometric measurements of dental bar are taken by digitalizing every bar with industrial CT or micro – CT. After digitalizing the dental bar the 3D model is created and compared to industrial 3D model (actual to nominal comparison). By analyzing the map of deviations received by the above we achieve accuracy up to 7 µm, that is why the Ortho Baltic bars match precisely the patients anatomy and are perfectly compatible with the whole All – on – (4-8) components.