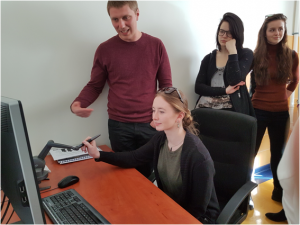

Today, 27th of March, Ortho Balitc was visited by a big group of bachelor students of Biomechanics (Vilnius Gediminas Technical University). Future biomechanical engineers spent quite some time in Ortho Baltic facilities familiarizing with the processes of modeling, manufacturing, and quality control for patient-specific medical devices – implants and surgical guides. Students were very interested in the non-parametric modeling tool we use for designing patient-specific devices, as well as in the 3D printing technologies: SLS, DMLS, InkJet.

Our Quality Control Laboratory with the equipment of microcomputer tomography (μCT) and 3D coordinate measuring machine (CMM) got a lot of attention as well.

The working processes of traditional Ortho Baltic activities – manufacturing of patient-specific footwear and patient-specific carbon orthosis were also introduced for visitors. Students also had an opportunity to try using 3D scanning, which is a service of Smart Factory – a company of Ortho Baltic Group.

We seek to cooperate with various universities in order to educate students and show how their knowledge can be applied in real working practice. Also we are very glad to see the latest technologies we use in our medical device manufacturing processes inspire curiosity in young minds.

Dear students, follow your curiosity and do not stop learning!

Creativity is intelligence having fun

[Albert Einstein]